Not known Factual Statements About Aws Cwi

Table of ContentsUnknown Facts About Aws CwiSee This Report on Aws CwiThe smart Trick of Aws Cwi That Nobody is DiscussingThe Facts About Aws Cwi RevealedWhat Does Aws Cwi Mean?

Third-party quality assurance assessment of steel fabrication facilities on welding inspection, as well as assessment of bolting and paint of structural steel. KTA's steel examiners offer Quality Control (QC) examiners to supplement fabricator's/ service provider's in-house QC personnel and on projects that mandate preserving the solutions of a qualified inspector (e.g., CWI) used by an independent evaluation company.Examiners carry out visual examinations of material for conformance with the authorized specs, plans and codes, along with confirmation of Qualified Product Examination Reports (CMTR) for products used. Materials and components are observed at bottom lines along the manufacturing procedure in both steel mills and steel fabrication shops. KTA's qualified welding inspectors likewise witness welder and welding procedure certification examinations as applicable to the scope of the project.

Steel manufacture examination services likewise consistently include performing non-destructive testing (NDT), also known as non-destructive examination (NDE), consisting of Magnetic Bit Testing (MT), Ultrasonic Testing (UT) and Liquid Penetrant Evaluating (PT) (Weld Inspector). Evaluations occur in steel mills and manufacture shops throughout the United States and on-site in the area and consist of all varieties of frameworks including bridges, arenas, buildings, towers, poles, and indicator structures

Aws Cwi for Dummies

KTA gives assessment services for the construction of bridge girders, bearings, grid deck, indication frameworks, light and website traffic poles, pedestrian bridges, and other freeway elements. KTA additionally offers these solutions for construction of structural steel for structures, storage tanks and pipelines. KTA's examination solutions consist of coating examinations covering surface area preparation, painting, galvanizing, and metalizing.

KTA's ideology is to respond swiftly to clients' requirements, match the appropriate examiner to the job, and provide the requisite documentation. KTA has the support personnel to offer technological consulting to the field employees and to the client. KTA has experts available to seek advice from on welding, NDT and finishings.

FST Technical Services is your international partner in the Semiconductor and Drug Industries! Our settings consist of benefits such as medical, dental, vision, life, 401(k) with company match, PTO, paid holidays. Come sign up with an outstanding group in an interesting, quick paced, and ever-growing industry! We are seeking a CWI's and/or NDT Level II licensed Welding Inspectors from in and around the Lithia Springs, GA location! Area prospects are encouraged to apply however this placement is open to travelers with mobilization and month-to-month daily for those living outside the area.

The Definitive Guide to Aws Cwi

Semiconductor, Consumer Products, Biography & Biopharmaceutical, and so on. Perfect prospect will have high purity piping inspection experience. Current AWS certs are wanted. CWI's and NDT Degree II's highly urged to apply.

Pro QC's third-party welding assessment services include: Paper Testimonial Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Testing (NDT) Others Our welding examination records are provided within 24 hr and record all examination points appropriate to quality, including all identified weld imperfections and digital images (Certified Welding Inspection) (https://www.40billion.com/profile/999225773). Pro QC's group of inspectors delivers third-party welding inspections around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the United Kingdom, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the USA, Mexico, copyright, Brazil, Peru, and much more nations

Assessment of the welding work is crucial for proper quality When your company is managing significant projects with demands for 3rd party independent welding assessment, we supply outstanding welding witness assessment solutions to confirm that welding has been done according to a lot of applied welding standards and specifications. AQSS executes welding examination services for clients from a range of industries.

Aws Cwi Things To Know Before You Buy

Not complying with effectively certified welding procedures often causes a weld of subpar quality, which can raise the fabrication's likelihood of failure under desired service problems. By evaluating for flaws, our assessors can help customers make certain that their welds meet relevant requirements of quality guarantee (CWI Welding Inspector). Weld assessments are conducted for numerous reasons, the most typical of which is to identify whether the weld is of ideal top quality for its designated application

The code and typical click for info used depends on the sector. Our welding examiners have the required certifications with years of experience with evaluation and recognize with a lot of used welding criteria and specs. AQSS has actually CWI certified assessors. We carry out these services using a variety of nondestructive screening (NDT) techniques: The assessment is performed in accordance with appropriate codes, such as American Welding Culture (AWS), American Culture of Mechanical Engineers (ASME), and Military (MIL-STD) typical specifications.

4 Easy Facts About Aws Cwi Described

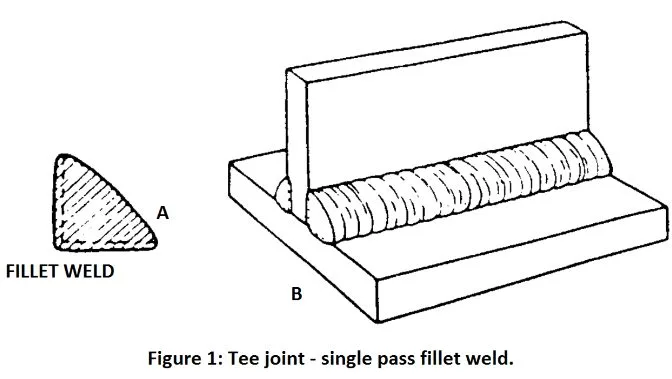

Weld evaluation of laser and electron beam welded parts typically complies with 3 distinct courses: aesthetic inspection; devastating screening; and non-destructive testing (NDT). entails taking a look at a weld with the naked eye and/or with some degree of magnifying. Normally, our inspectors are looking for splits, pits, surface pores, undercut, underfill, missed out on joints, and various other facets of the weld.

Samples can also be taken at intervals during the production process or at the end of the run. Damaging screening examples are precisely cut, machined, ground, and brightened to a mirror-like coating. An acid etch is then related to aesthetically bring out the weld, and the example is then examined under a microscope.